Categories

New Blog

Application of hot melt adhesive automatic scraper

March 21 , 2025In modern manufacturing, hot melt adhesive is widely used in various industries, including packaging, woodworking, electronics, and automobiles. However, the traditional manual scraping gun method has some inconveniences in large-scale production, such as low production efficiency and high labor costs. In order to overcome these challenges, engineers have developed hot melt adhesive automatic scraping gun technology, providing companies with a tool to improve efficiency and reduce costs.

Limitations of traditional manual scraper guns

In traditional hot melt adhesive applications, workers need to manually bring the hot melt adhesive gun close to the target surface and manually control the spraying and scraping process of the hot melt adhesive. This method has several disadvantages. First, the manual scraper gun needs to be repeatedly positioned and controlled, and the errors caused by this are difficult to avoid, resulting in uneven coating and unstable quality. Second, long-term use of manual scrapers can easily cause worker fatigue and reduce worker work efficiency. In addition, manual scrapers also cause waste of hot melt adhesive because operators often find it difficult to accurately control the amount of hot melt adhesive used.

Advantages of hot melt adhesive automatic scraper

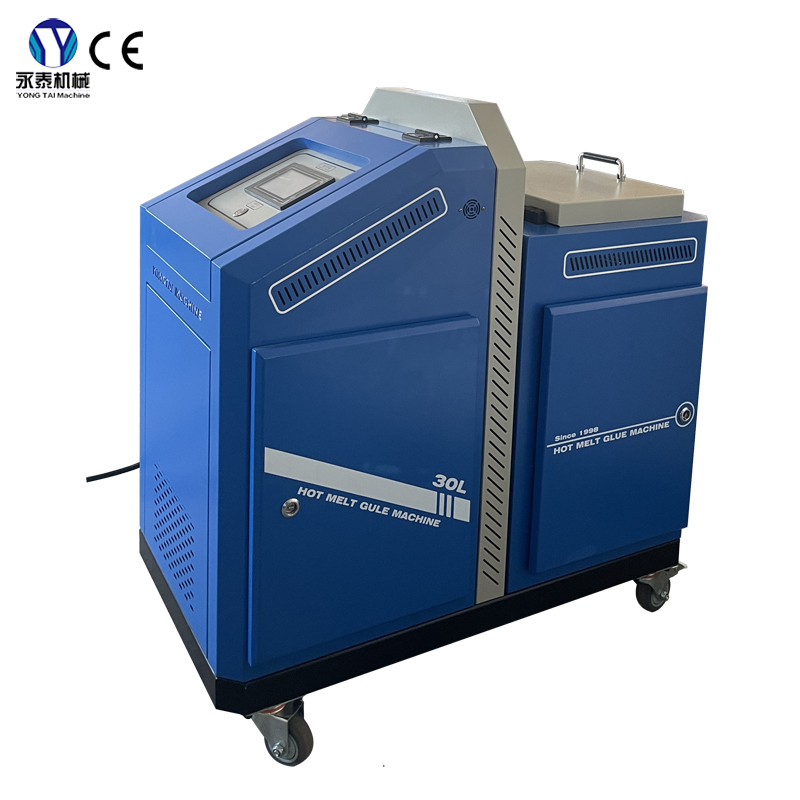

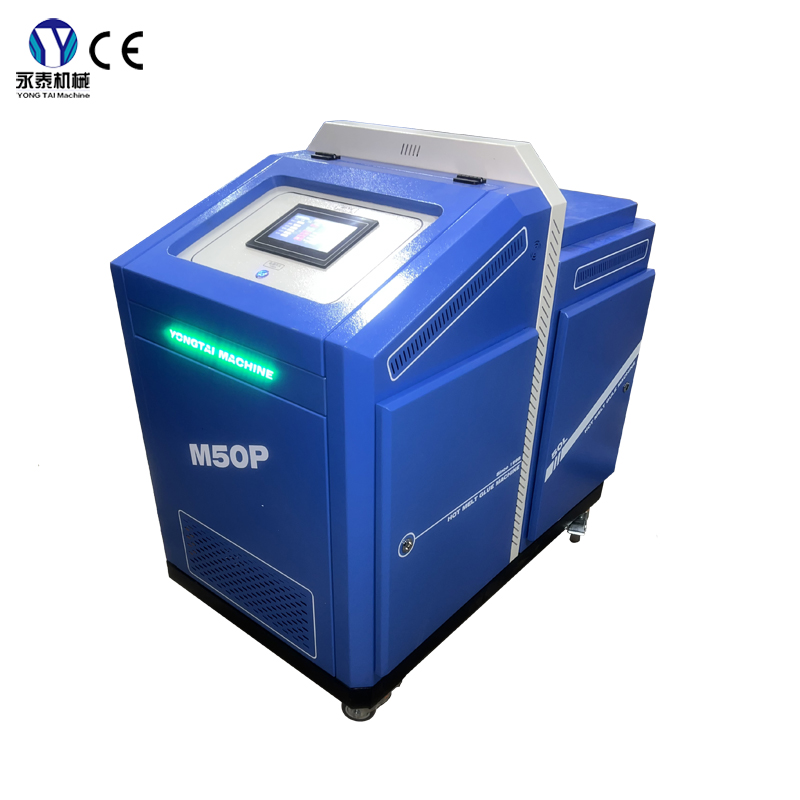

In order to solve the problems of traditional manual scraper, automation technology is gradually applied to the hot melt adhesive field. The hot melt adhesive automatic scraper system consists of a coater, a sensor and a control system. The coater can spray the hot melt adhesive evenly onto the target surface through precise control. At the same time, the sensor can monitor the shape and state of the target surface and automatically adjust the height and speed of the scraper to ensure the consistency and accuracy of the coating. The control system can realize the automated hot melt adhesive scraper process according to the preset parameters and process requirements.

Application fields of hot melt adhesive automatic scraper

Hot melt adhesive automatic scraper technology has been widely used in many industries. In the packaging field, it is used in carton sealing, bag sealing, tape bonding and other links to improve production speed and quality stability. In the woodworking industry, hot melt adhesive automatic scraper can be used in furniture manufacturing, board bonding and other processes to improve production efficiency and product quality. In the electronics industry, automatic scrapers can be used in circuit board assembly, component packaging and other processes to improve work efficiency and reliability. In the automotive manufacturing field, hot melt adhesive automatic scraper can be used in body sealing, interior bonding and other processes to improve bonding effect and product reliability.

The application of hot melt adhesive automatic scraper technology has brought great benefits to all walks of life. It can improve production efficiency, reduce labor costs, ensure the consistency of coating quality, and reduce the waste of hot melt adhesive. With the continuous development of automation technology, hot melt adhesive automatic scraper will be used in a wider range of fields and continue to create greater economic benefits and development opportunities for enterprises.